Heat exchanger units are valuable pieces of equipment for operating in not only big industries but also household as well. These special devices are designed to maintain a certain temperature in large areas while also ensuring that the air we breathe is clean and fresh. Today we are here with a complete tutorial over heat exchanger units. We will look at how they function, why you need them and the best one based on what you have/need in this article.

Ever been in a room that's way too hot, or one that is freezing? This probably means you know how important heat exchanger units are compressed air applications. These systems work to regulate the temperature in a room, ensuring that individuals are kept comfortable and safe. In factories, the heat exchanger units are of a more important nature. They maintain the correct temperature of machinery and products, which is critical for ensuring everything operates appropriately.

Machines tend to release heat whenever they are at work. It can therefore damage the machines and even create unsafe working conditions if it is not drained out. Which is why you need heat exchangers — not a good idea, but necessity. That help keeps everything running smoothly while also safeguarding the equipment — not to mention those who interact with it.

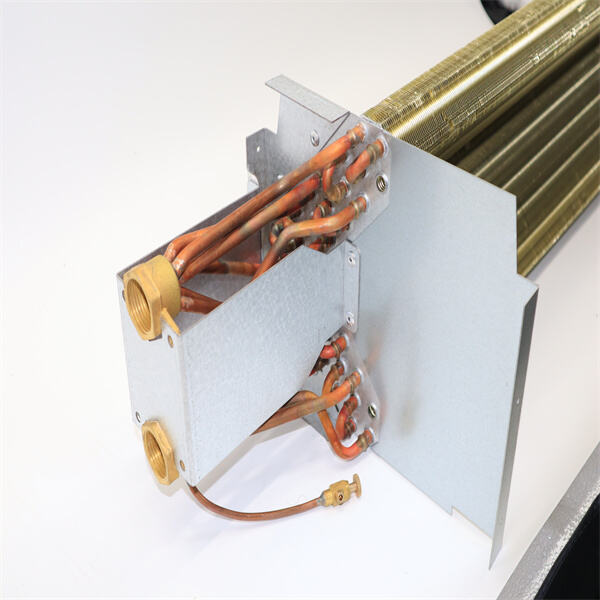

But how do HVAC heat exchangers work in practice? Heat exchangers move heat from one liquid to another. Liquids can circulate inside one tube that is within another in most manufacturing facilities. This is a typical process for heat exchangers. The two fluids are flowing right along side each other and do not mix. Instead, heat moves across the wall separating tubes. It is known as a shell-and-tube heat exchanger.

In other cases you may have a liquid flowing thru an enclosed metal box, or tube and another liquid passing over the outside surface. Air-cooled heat exchanger — this is the type of heat Exchangers. Air-cooled heat exchangers are typically used for electronic equipment, large generators and other kinds of machinery. They simply assure that everything runs at an appropriate temperature to keep the machines running smoothly.

There are many factors to consider when choosing a heat exchanger. The first place to start is with the size of area you are going to put your heat exchanger in. Then think what is the heat that space generating?! The types of liquids with which the heat exchanger will work must be taken into account.

Important point to note when selecting a heat exchanger, it is the efficiency and type of liquid that will be exchanged with. What the device does, in essence, is transfer heat and keep large volumes of air or liquids at controlled temperatures through pre-set ductwork that connects to fans/vents while it comes across the different types of heat exchangers i.e., plate type design shell-and-tube configuration and even a custom-built cooling body treated as an air-cooled system. Which type you use will ultimately depend on your requirements and when youre installing it.