Evaporator heat exchangers are significant devices used in industries to relay the lost and extraneous laden thermal energy of hot liquid into any cold liquid. And the importance of these devices is not very demanding to explain. They are used to cool the air inside, for example in refrigerators. It can get its job done by absorbing heat from the outside air and cooling the indoor air. This is the reason that we fell cold air when opening fridge. In addition, these heat exchangers are combined into the creation of several chemicals and in many other manufacturing procedures so that they may take part as a substantial component amongst various industries.

This is a very serious process for large industries. For instance, in an environment where different chemicals are to be made and separated from each other the evaporator heat exchangers aid by making them too hot. Then when the heat is introduced on them, they start to convert into gas. These new steps would more effectively sort the chemicals into their constituent components, making them easier to be used by workers in other products.

There is actually one very huge advantage to using evaporative heat exchangers, and that factor would be the amount of energy they save. They quickly absorb and release heat by transporting it around in fluids. So there is less energy being used in entirety, which not only saves the environment but also allows for factories to cut back on how much they spend on their consumption of elecrricty. Saving energy for businesses results in much lower prices on products as well!

But with the yin there's also a little yang. The problem is that these devices are expensive to make and also even more so to repair when they stop functioning. Since they are crucial for many endeavors within the production process, a failure can inevitably result in costly delays. And the heat exchangers need to be maintained and designed properly in able for it to function quite complicating inside a factory.

Evaporator heat exchangers have to remain in good shape because great maintenance means they get utilized well. We will take the time to explain how you can do that but, in a nutshell, it means inspecting them frequently for any signs of deterioration or damage which could prevent as-efficient running. Regular maintenance is key! It's also a good idea to take the time now and again to clean them properly so no dirt or anything else gets too built up inside that might prevent liquids passing through.

One more tip is never ever to operate the heat exchangers with a wrong liquid. Any chemical is potentially harmful and can lead to the harm of Heat exchanger parts. That is why the selection of a suitable material and liquid that does not have an effect on what can be processed by heat exchanger must be well-looked over. That guarantees them functioning for a long time.

Another modern trend has been to use improved liquids for more efficient heat transfer. New heat exchangers that use water as a moving fluid can afford more efficient cooling than older liquids. Many of these newer fluids are also eco-friendly, and that's a big factor in many manufacturing jobs. Replacing the materials and fluids for better environment ones is a sustainable development in industry.

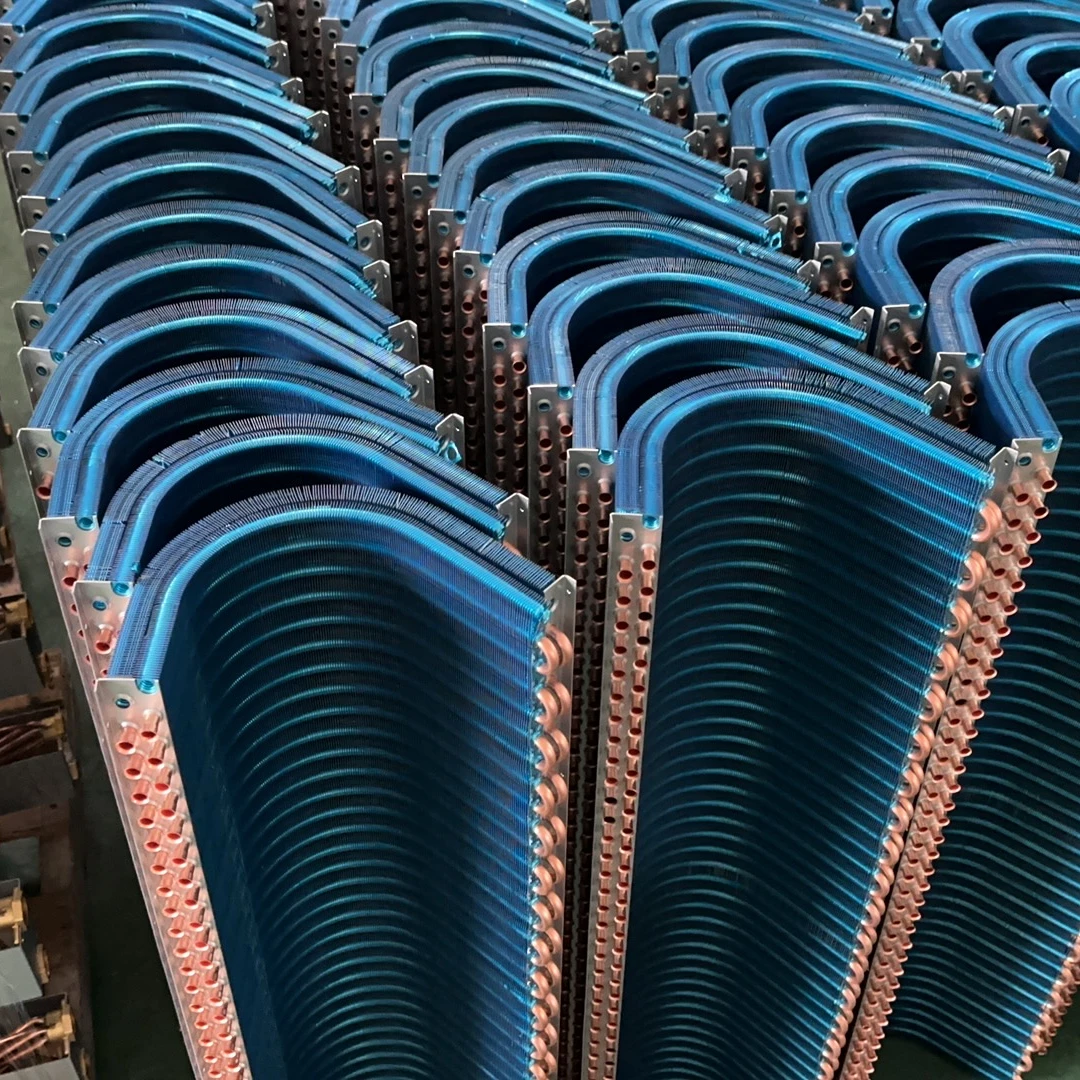

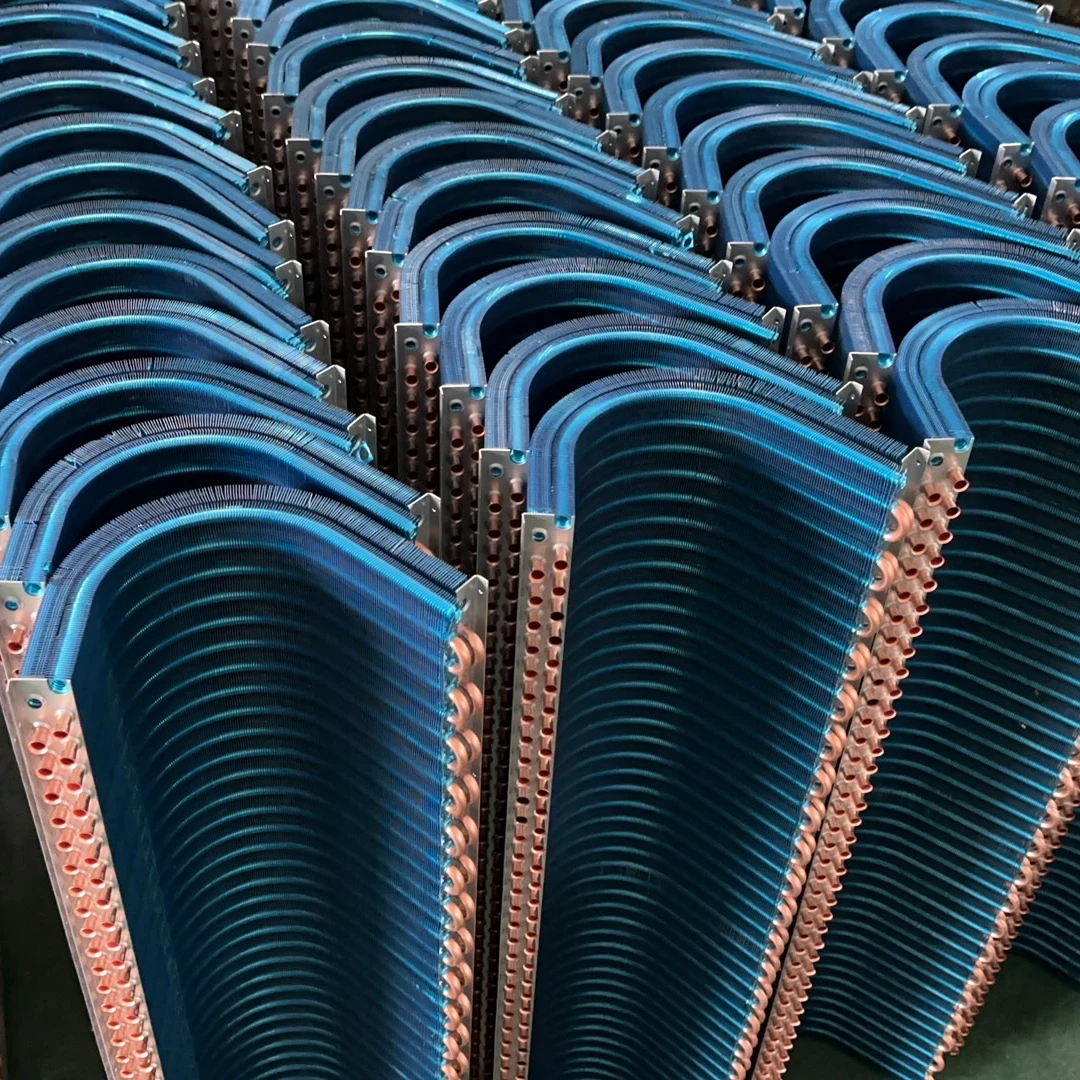

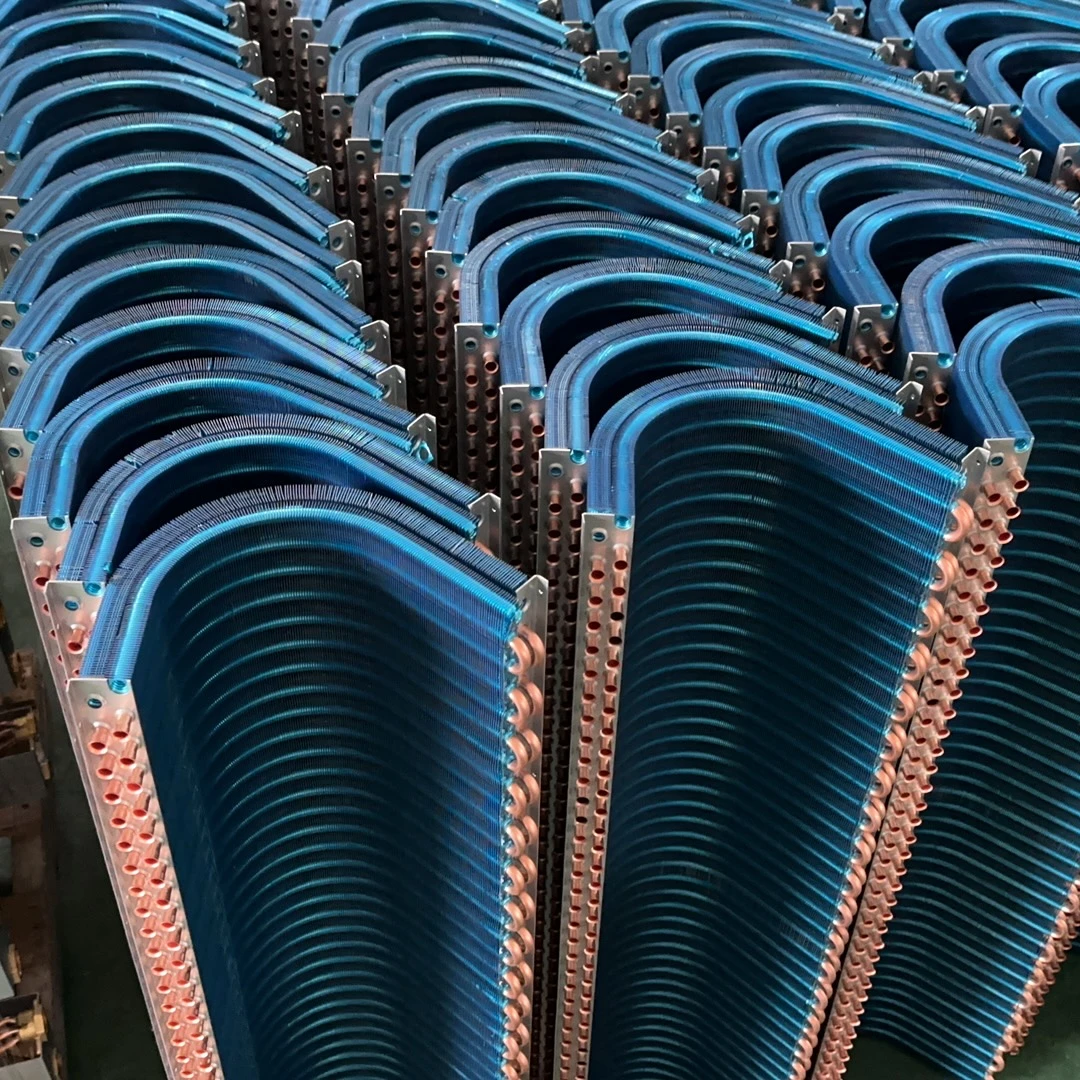

Since establishment 2007 SHUANGJUN Electric Appliance Co. developed a well-established company mainly manufactures refrigeration equipment. evaporator heat exchanger progress development past two decades, today we the most renowned machine manufacturer solution provider refrigeration HVAC industry.

products include heat evaporator heat exchanger, air conditioning indoor units air conditioning systems other fields, which comprehensively cover needs in field. products suitable diverse scenarios commercial, industrial bathrooms kitchens.

sales consultants richexperiences both after-sales pre-sales. They'll quick respond your questions, tailor products evaporator heat exchanger possible time, offers reasonable transactions rates industry.

company utilizes evaporator heat exchanger design heat transfer simulation other methods aid each customer equipment designs matching high efficiency. offers extensive customizations meet customer needs. One-stop solutions designed starting scratch turnkey projects implemented.