Heat transfer is a crucial phenomenon which finds application in many machines and our homes. This is the process of transferring heat from one thing to another, such as heating or cooling something. When you heat water for tea, or when a refrigerator cools down your food — these are uses of heat transfer. Many years ago, heat exchangers were limited to using straight pipes which resulted in them working below their design efficiency. With the new spiral heat exchangers, this problem is taken care of and one can transfer available energy from source to sink with much better efficiency.

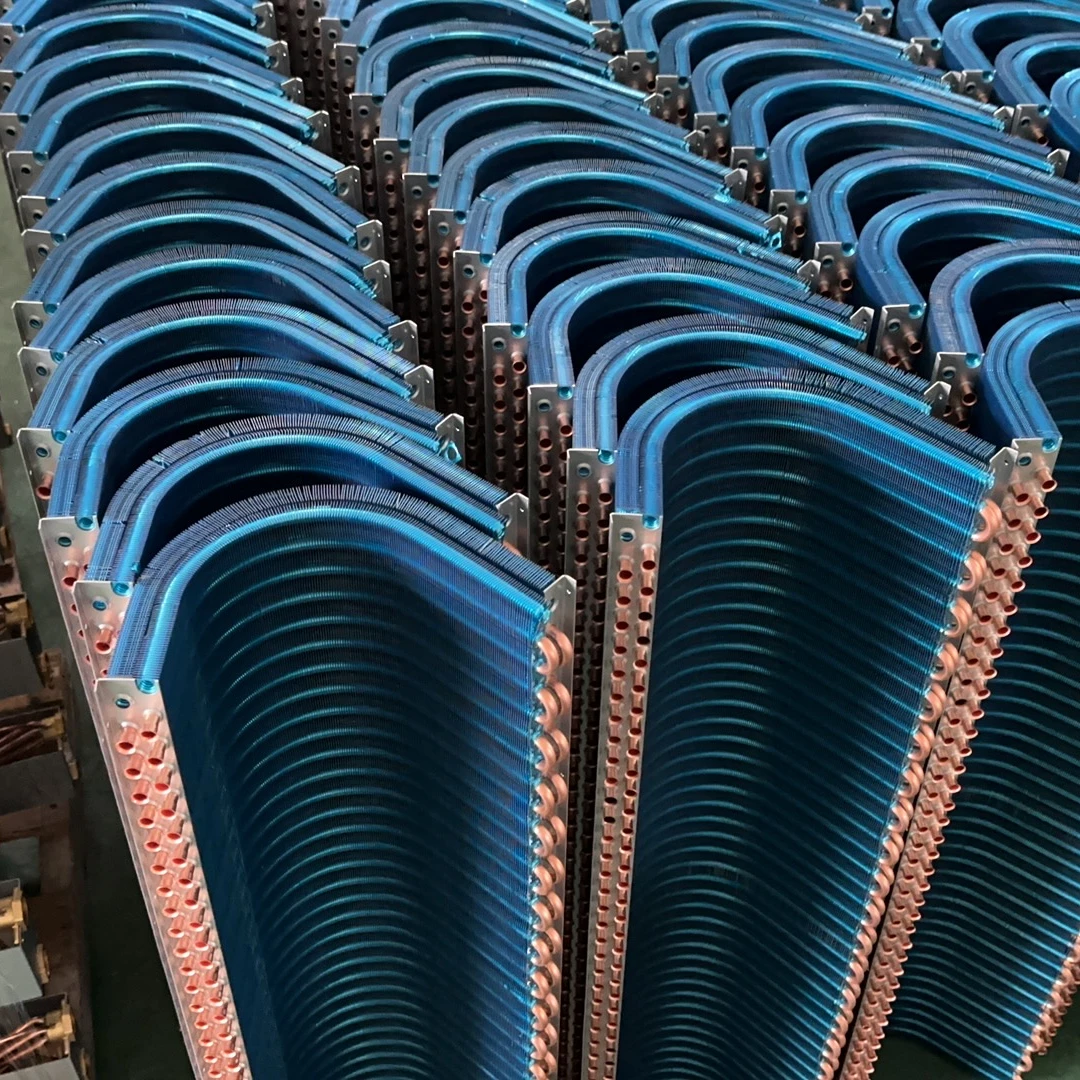

A spiral heat exchanger simply uses a set of skinny, twisty tubes instead because they have more surface area and work better (source). It is similar to a slide in the playground! A pair of liquids flowing without stopping, just like when kids slide down a clear tube—twisty but not too twisty to bump into each other. This consistent movement allows the liquids to combine for better thermal transfer between one liquid and another. FoodScience quest of the day: The more they mix up, better everything should be communicated by it and handled as well in case fluids are involved.

The advantage of the spiral heat exchanger is that it can transfer large quantities of heat much faster than previous designs, and therefore they are coming to availability. In various applications such as oil companies, power plants or food factories. Such industries require quickly and efficient heating & cooling of liquids, which can be done through spiral heat exchangers. The spiral tube form allows the liquid to move through the middle, allowing for direct excellent heat transfer. So processes in these industries can be performed faster and with fewer resources.

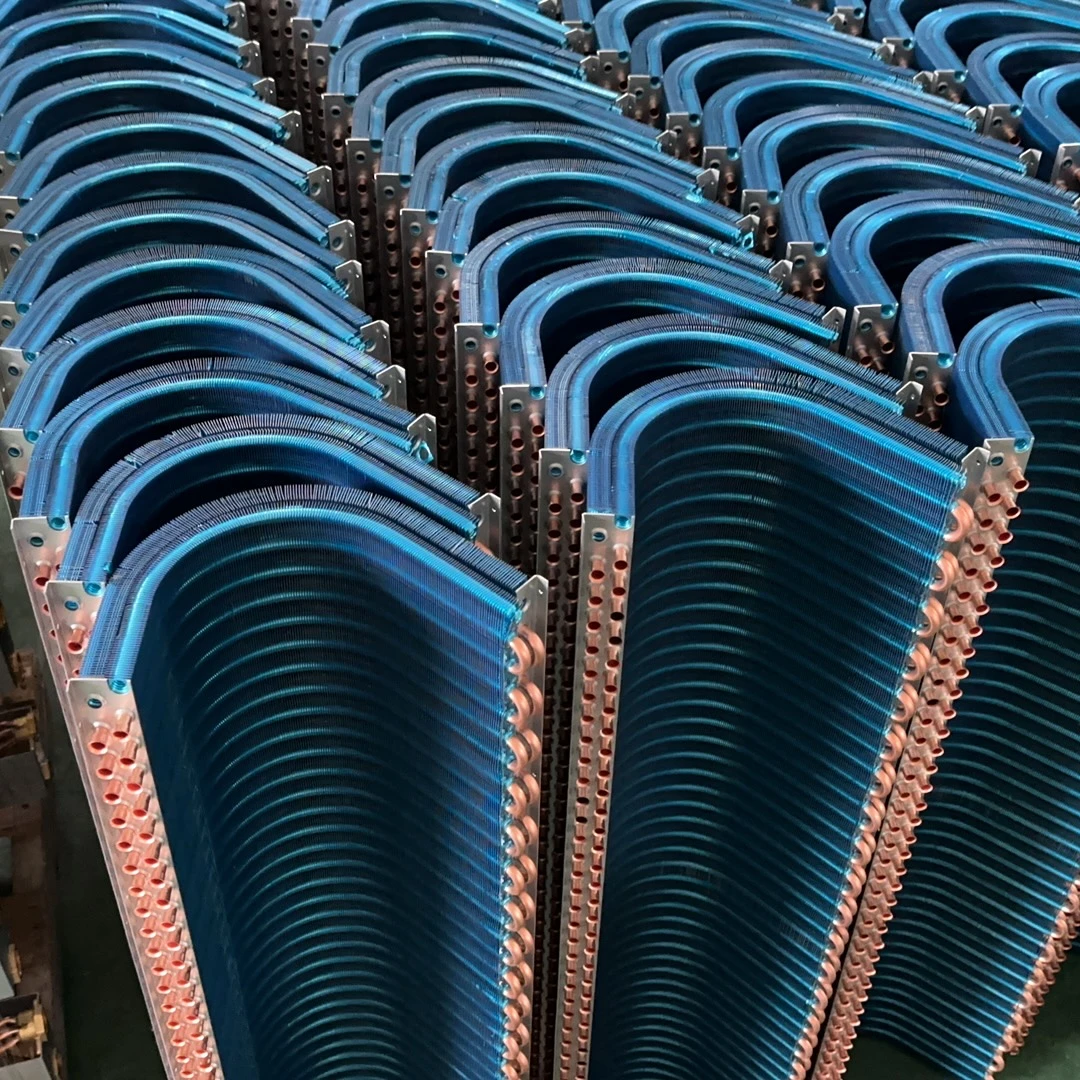

Spiral Heat Exchanger saves a lot of space and weight in their designs. Meanwhile, the spiral heat exchangers leave footprints similar to their old cousins and can be slotted into tight nooks. This is particularly useful when space to work in so a limited resource such as smaller factories or plant. They are a space saving too, so they make it easier to install the equipment and keep all your awesomeness organized.

One challenge to the more traditional heat exchanger designs of yesteryear was a pesky problem known as fouling. Fouling occurs when the heat exchanger will accrue anything — dirt, particulate and so on. This build-up makes it more difficult for liquids to suck through the pipes but also decreases that transfer of heat from one fluid to another. Fouling may arise due to various reasons including the type of liquid used and its temperature. Unattended, this can result in problems and higher costs.

The good thing is that it incorporates the spiral tube, technology which in turn cam help to avoid dust and coming food particles sticking on the surfaces. The twisty tube helps better guide the liquid, which less dirt is accumulated over time. You know — the same way a nice slide will keep your kids from being trapped halfway in between! Furthermore, the heat exchangers are more durable with spiral tube technology so that you do not have to worry about repaires and spending money on them. Which is perfect for businesses, as it decreases maintenance prices in the lengthy term.

In this way, it is also designed to be able to function effectively in harsh environments as a spiral heat exchanger. Heat exchangers are often subjected to extremely high temperatures and pressures, yet a reduction in wear is still evident due the spiraled design of the tubes. This results in a longer and more efficient life of the equipment. This design requires less heat exchangers in general, which saves money on civil and equipment.

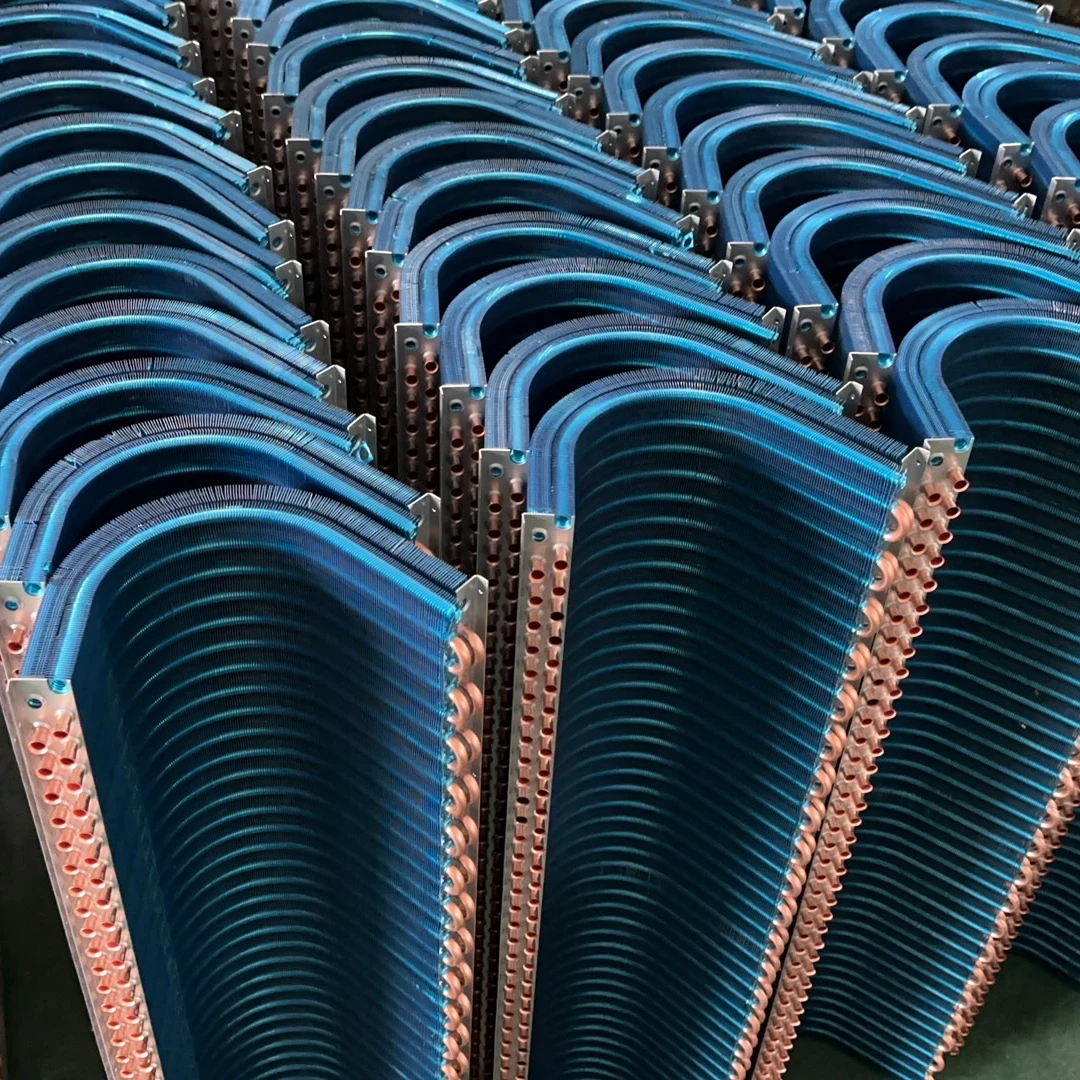

helical heat exchanger include heat exchangers as well air conditioning indoor units. have air conditioning systems. products suitable diverse scenarios commercial, industrial kitchen/bathroom.

helical heat exchanger 3D design software as well heat transfer simulations, other techniques assist every customer design own equipment matched highest efficiency. We provide deeps customization orders meets demands customer. One-stop solutions provided starting scratch complete turnkey projects completed.

sales consultants helical heat exchanger experience field after-sales as wells pre-sales. They'll respondpromptly any inquiries have, designs products shortest possible time will offer most affordable transaction costs industry.

SHUANGJUN Electric Appliance Company. which founded 2007 grown helical heat exchanger reputable company specializes manufacture refrigeration equipment. Through continuous development advancement over past two decades, now are becoming top machine manufacturer solution provider HVAC Refrigeration industry.