The Significance of Heat Exchanger Stability

Shell and tube heat exchangers are important for different areas where warmth move is needed to complete work forms. At its core, a heat exchanger is a device that enables the transfer of thermal energy between two fluids. A heat exchanger is no doubt an essential tool for these industries, and without it they will experience a challenging environment to operate in. This blog will help you discover the world of top 5 quality heat exchangers - which ones are most efficiently run across benefits, technology innovation,safety features, operational how-to's, industrial-grade assurance to application versatility.

Advantages Of Heat Exchangers

Heat exchangers have a wide range of benefits in many different industries and sectors. Besides helping saving energy, reducing cost, increasing efficiency and environmental sustainable. Applications include industrial uses (such as automotive, heating ventilation and air conditioning systems -HVACs - can power generation among many others).

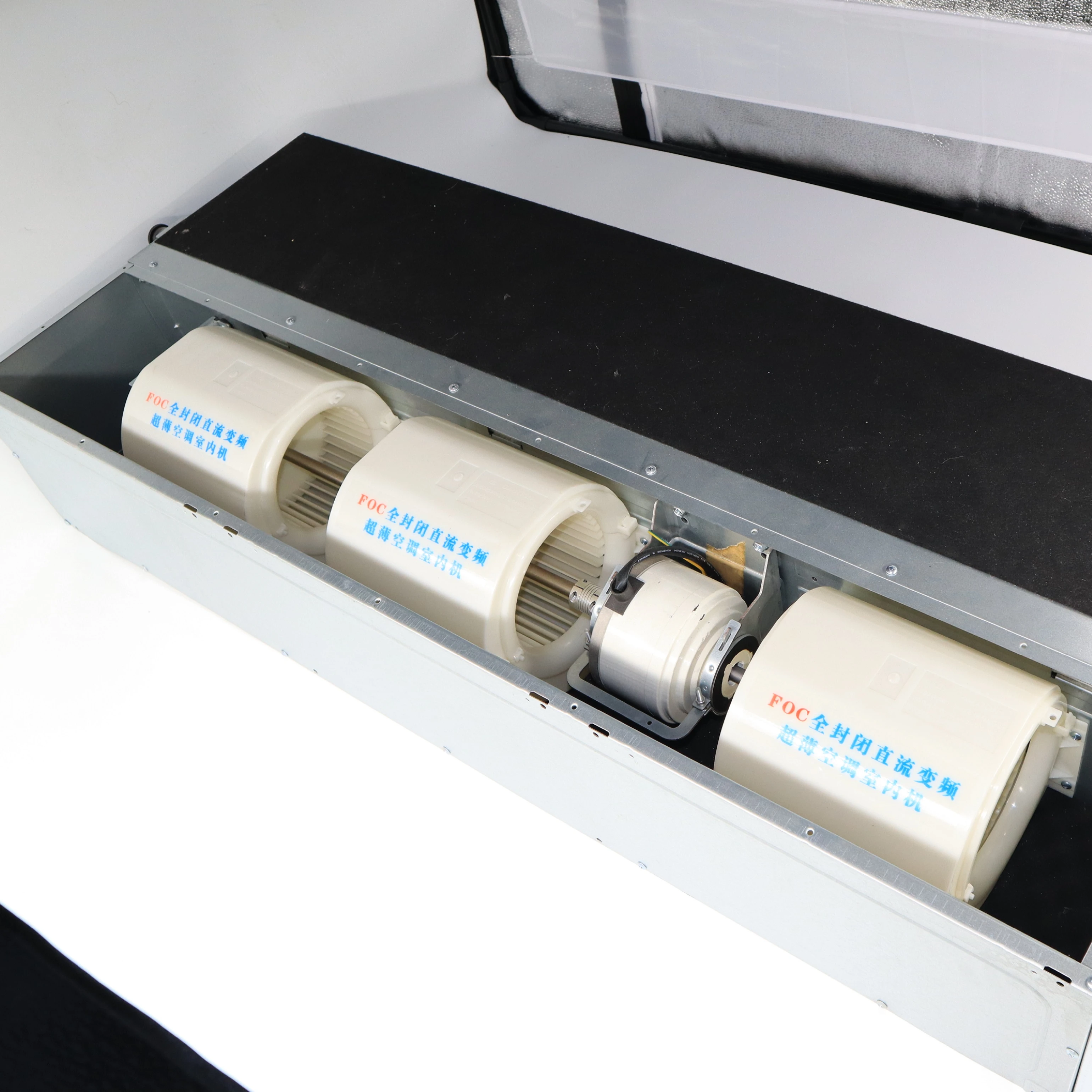

Advancements in Heat Exchanger Technology

Heat exchanger technology continues to evolve and drive the development of heat exchangers. These devices are not perfect, which is why manufacturers try to produce better versions as time passes. These days even heat exchangers have become smaller, thanks to their more sleeker design; and that too without any compromise on efficiency. In addition to that, some companies add durable materials such as titanium, which further reinforces the longevity of heat exchangers.

Safety Considerations of Heat Exchangers

Safety is also a serious issue in industries Though past incidents have underscored safety issues with heat exchangers, manufacturers have produced rules and developed better designs incorporating safer materials. This has made heat exchangers more safe with features like explosion proof designs and leak prevention materials.

Correct Use of Heat Exchangers

To get the most out of a heat exchanger, it is essential to adhere to manufacturer guidelines for installation and upkeep. Correct installation and periodic service by qualified engineers may reduce the potential for such faults, but cannot eliminate all of them. Inspection should always be performed for damage or leaks in the exchanger before using it.

World of Service Excellence & Products

The quality of a heat exchanger means the reliability. The best heat exchangers are also able to perform better with less energy, which is why they have a long life and require lower maintenance. Moreover, it is the responsibility of manufacturers providing proper after-sales support - such as troubleshooting and regular service checks- that heat exchangers will continue to function at their best.

Apllicaion of Heat Exchangers

Heat exchangers are widely used in the automotive industry, power generation and food processing among others. These are used for purposes of power generation, water heating or cooling and chemical processes. Facilities like HVAC systems, chemical processing plant power plants and food manufacturing will rely heavily upon the use of heat exchangers.

So, It should be clear to you that proper heat exchanger selection is necessary for the trouble-free operation of industrial operations. Whether the incredible benefits, innovation or safety features of a heat exchanger are key requirements can help determine which product may be best suited for specific operational guidelines as well significantly reduce overall facility operating costs.

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

UR

UR

LA

LA

MN

MN

TA

TA

MY

MY

KK

KK

SI

SI

UZ

UZ