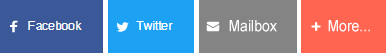

If you prefer everything to be chilled, then heat exchanger is an efficient device that gives coolness. Heat Exchanger is the device for transferring heat from one fluid to another, or both fluids to each other even in same state.

The benefits of the heat exchangers are just immense. The first and most important thing is that they are extremely energy efficient, which means it uses relatively less electric power to cool down the substance effectively. This is not only good for our environment, but saves us all money in the long run. Second, they are also very compact - the heat exchangers. These chillers are compact enough that they can be fitted into tiny spaces where other AC systems might find it difficult to go. Secondly, Stability is a crucial advantage of heat exchanger. They are also built to last, which makes them a perfect choice for any application where longevity is desired.

The heat exchanger industry is an innovation that has been at the heart of it. Manufacturers are always looking at ways to create new and better designs for heat exchangers that offer a higher level of convenience in operation. One example of this is the plate heat exchanger which uses a small plate metal to aid in transferring heat flow between two fluids. Efficiency aside, this groundbreaking design also ends up being more cost-effective than the typical tube heat exchangers.

Safety is a number one concern for heat exchanger manufacturers. Safety mechanisms to avoid calamities are combined because these devices work in high manifolds of pressures and temperatures. For example, the pressure relief valves are required to take care excess pressures while the temperature sensors ensure that if system temperatures reach unsafe limitation; it shuts itself down.

In fact, the variety of applications heat exchangers service is mind-blowing. They are used in many applications including cooling HVAC systems in buildings, cool steam condensers and even space shuttle engines at launch. There are more commercial applications where this type of pump is used, such as in the food processing industry to cool products like milk and juice because you can change the temperature resistance just by changing thematerials they make each part with.

The use of a Heat Exchanger is quite easy! One fluid or gas that requires heating flows through one side of the heat exchanger, while a second gaseous or liquid flow across from it goes in the opposite direction. This effectively transfers heat from the hot fluid or gas to the cooling medium, producing exit of the latter at a lower temperature.

Heat exchanger manufacturers provide a variety of services to their customers. This includes installation, maintenance and repair services as well training programs to ensure that our customers are familiar with how the heat exchangers operate efficiently.

Quality of the heat exchanger- Similarly a heating exchanger must be good enough. When it comes to the heat exchanger, other than its long service life,It is also maintenance-free frequently as well. With the use of premium-quality materials and through-hours testing processes, manufacturers follow strict quality control regulations to ensure performance.

Heat exchangers are used in a wide array of applications These are used in various industries such as automotive, food processing,HVAC and power generation. Not only that, but they also play an important role in residential heating and cooling systems.

Conclude As a result, Heat exchangers are essential for various industries. These are highly opted for due to their range of benefits, such as energy efficiency, compact design and dependability. Following: Manufacturers carry on pioneering new technologies, promoting advances in design, performance, safety and build quality. The market is flooded with a number of excellent heat exchangers from the top heat exchanger manufacturers, be it for personal use, residential or industrial.

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

UR

UR

LA

LA

MN

MN

TA

TA

MY

MY

KK

KK

SI

SI

UZ

UZ