Thermohydraulic devices such as heat exchangers come in handy to transport heat between one fluid and another. They are essential in so many places, including buildings heating and cooling systems, chemical making processes and power generation for our homes as well us industries. Engineers and many technicians are fond of standard heat exchangers because theyre straightforward to use, completely reliable, and do not cost a lot. This text will show you everything about typical heat exchangers. We will see (i) what bolts are, and the benefits they bring along with common usage areas; then, we learn about various styles of its types to finally understand how you can maintain your bolt gear well and decide which one among these is the best for a particular job.

Heat exchangers are actually devices that allow the transfer of heat between a solid object and to a fluid, or between two visionaries. One example is where two fluids flow through the heat exchanger in opposite directions. Because one is always hot while the other cold. The heat goes from the hot liquid to cold one, crossing a barrier between them. This barrier could be an ordinary wall, or it may a specific layer that is able to transfer heat. Typically heat exchangers are produced of durable metals like stainless and copper. These doors can measure in a variety of shapes and sizes, depending on their applications and purposes.

Standard Heat Exchangers are used in various applications, including heating and cooling systems for buildings, chemical processing industry (in example production of ammonia), power stations (for generation of electricity)and the food & beverage factories. Its applications are countless and can be used for various purposes, like cooling, heating, taking gases to their liquids state which in turn help maintain temperature of other systems. It also makes them very versatile and highly sought after for a wide range of uses.

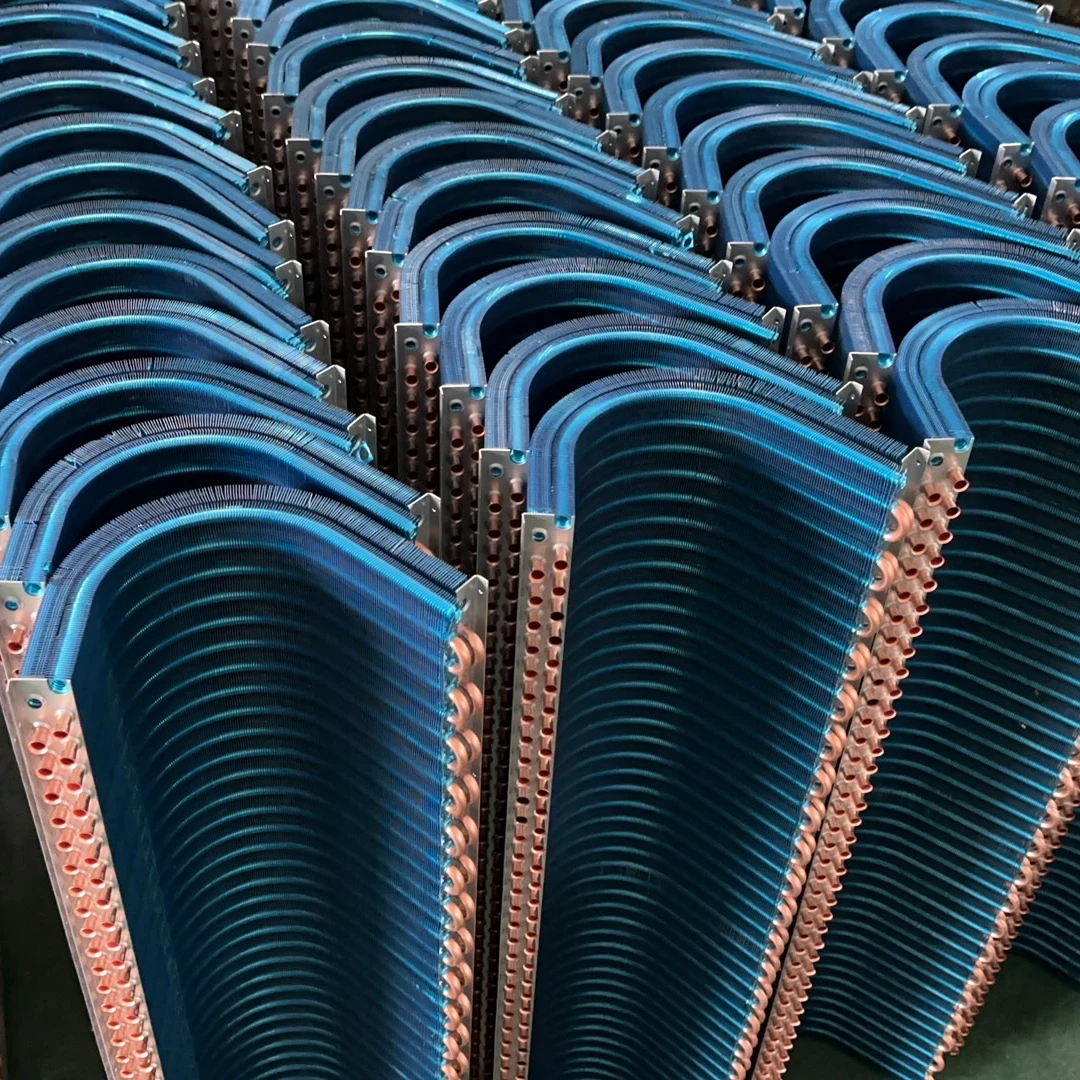

The shell and tube heat exchanger is what most people think of when they hear the term standard heat exchangers. Shell and tubeThis variety has a big shell that encases many smaller tubes inside it. The liquids flow through the shell and tubes, respectively. The walls of the tubes allow heat to be transferred, providing a means for two liquids that cannot mix to exchange thermal energy. The shell and tube heat exchangers are very versatile- it can be developed easily, as well efficient likewise easy for cleaning.

The last type of general heat exchanger is the plate heat exchanger. It creates of lots small sheets superimposed on one another Both the liquids go through alternate channels provided between two plates, heat is exchanged from wall of the plate. Plate heat exchangers are incredibly efficient and compact – this makes them good for use in tight spaces that you might find in a small factory units or domestic systems.

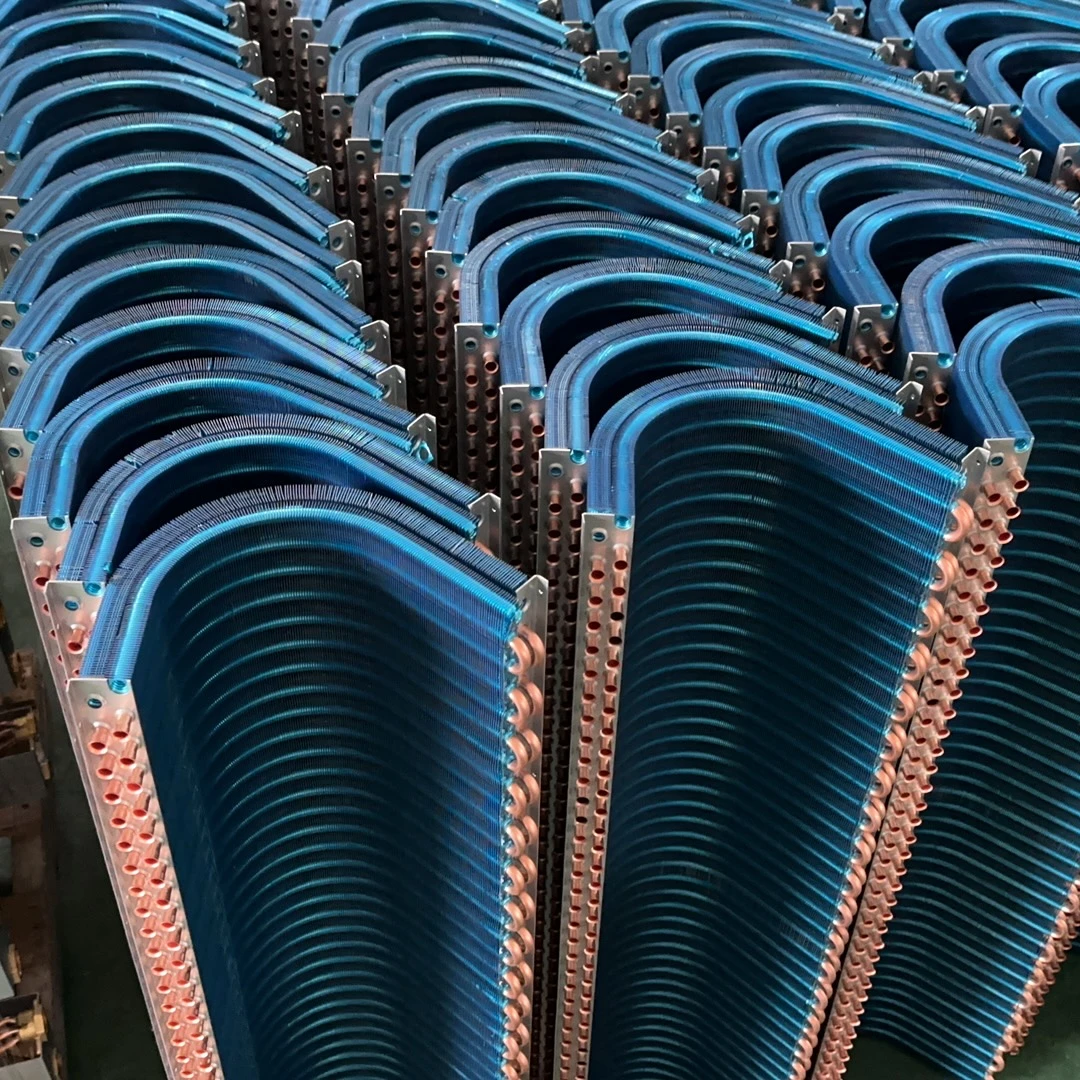

The maintenance requirements of a typical heat exchanger can vary according to the type, composition and service conditions. Every month the system needs to be looked at, surfaces need scrubbing and checking for leaks; every year it must have the tubes replaced as they get worn out from use — damned things never last very long anyway while gaskets (the rubber tired bumpers) changed if work is being done on them pressure levels then tested making sure that everything working properly. Heat exchangers that are not checked enough and serviced regularly tend to have problems.

When selecting a conventional heat exchanger, it is important to consider the amount of heat which will need to be transferred, what temperature range in which the system must operate at. What pressure limits does this exchanger allow? Are your liquids compatible with each other and have you taken into account fluid flow rates? Also consider how likely the system is to be soiled, what maintenance will need doing and costs generally.

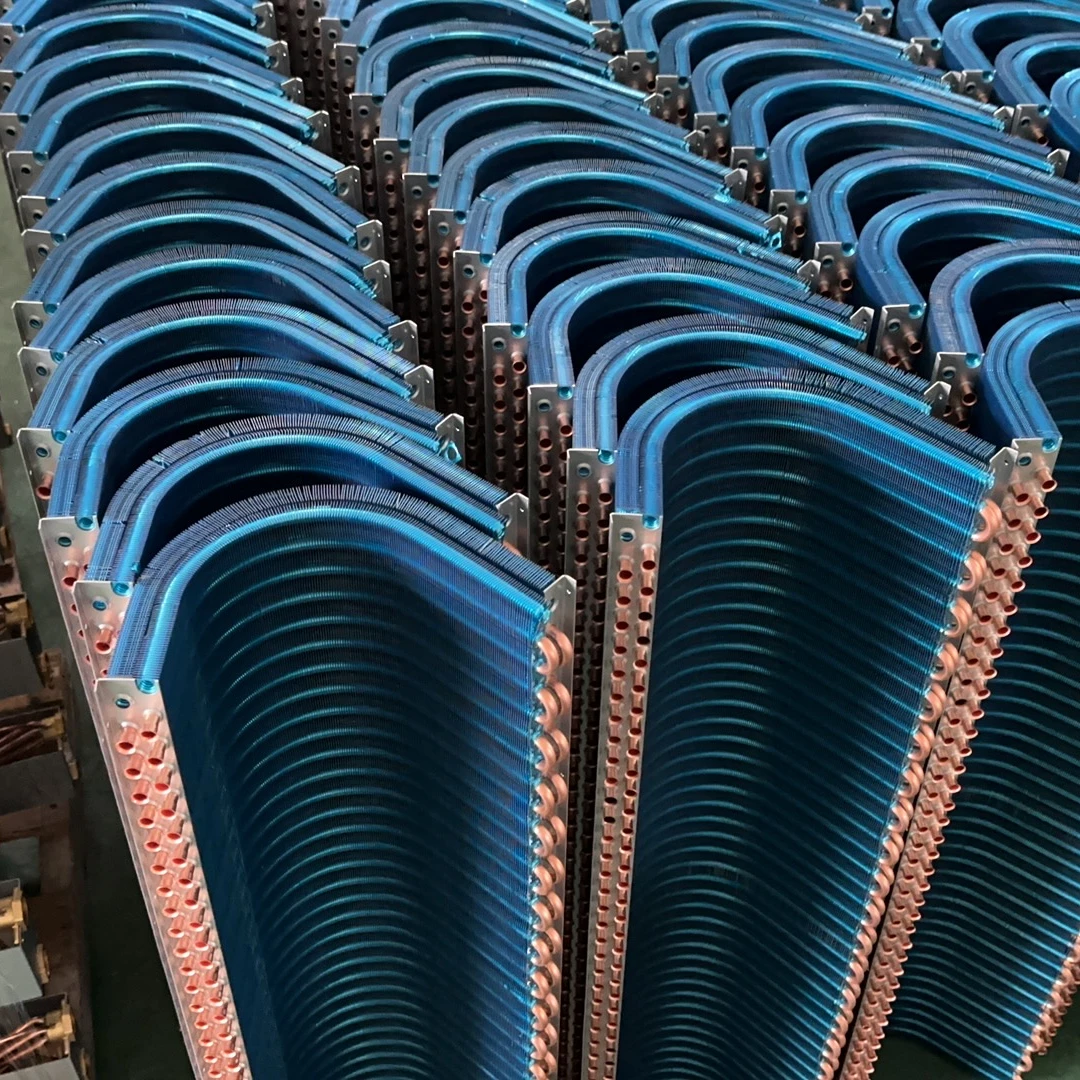

offerings cover heat exchangers air conditioning indoor units air conditioning systems, other fields comprehensively cover needs field. products standard heat exchanger various scenarios, including commercial, industrial kitchen/bathroom.

sales standard heat exchanger pre-sales staff a wealth experience both pre-sales phases after-sales phase. They'll responds swiftly inquiries, customize items you requires within shortest time possible, offer price-competitive transactions marketplace.

Since establishing company 2007, SHUANG-JUN Electrical Appliance Co. developed into well-established company mostly manufactures refrigeration equipment. We been developing progressing continuously last 20 years. Today, we the top machine solution provider refrigeration standard heat exchanger.

company uses 3Ds design as standard heat exchanger heat transfer simulation, among technologies assist each client design equipment matching maximize efficiency. offer deep customization meet requirements customers. One-stops solutions offered scratch, turnkeys projects are executed.