What about a fin fan heat exchanger? This is a unique tool that only allow in the transference of heat from one liquid or gas to another but never mix them. This is crucial, because in many cases we need to cool or heat this liquids and gases that are flowing through the heat exchanger. Heat Exchanger, which removes (or) adds heat from a hot gas to pass it into cooler gas mainly finds place and usage in many processes / operations. Such as:Fin fan type Heat Exchangers withdraws (transfers/removes)heatawayfromahotgasand providesittoacooldisk/petal assemblyortheyareequallyusedinthepropagation ofheatfromliquetogas). It is thus a very handy device to have around in many situations.

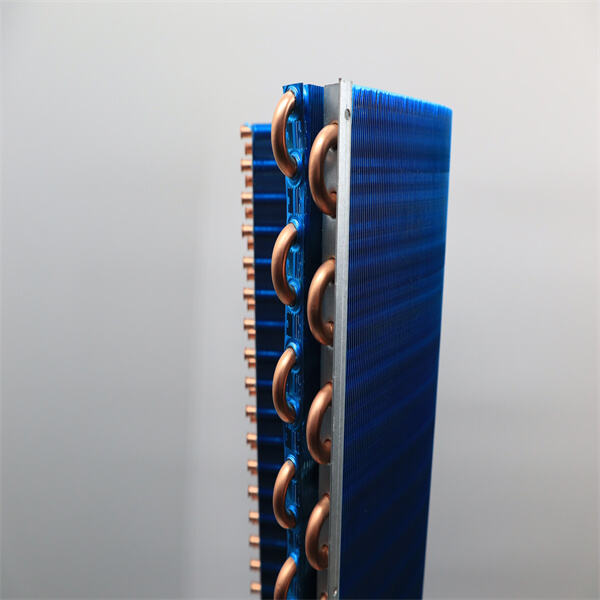

Fin fan heat exchangers —arctic fin fans -are the cooling-sort of plants with blades or fins fixed on outer side. Fins — they are included in the design so as to increase surface area of heat exchanger (i.e. fins helps us transfer more and more amount for a given space). The more area, the better and faster heat moves through — leading to a device that works even harder..better yet more efficient. That is why fin fan heat exchangers are one of the most commonly used types.

Named after their fan, the most prevalent sort is Fin Fan heat exchangers which are generally easier to deploy than other varieties of air-cooled devices (air fin coolers) yet can save much more energy by being used with economizers.

Now that we have understood this, can you guess how a fin fan heat exchanger also contributes to energy saving? It’s true! The fins on the heat exchanger create a bigger area so that they can extract energy as much from the fluid which passes through. This is beneficial because that fluid takes less energy to heat up or cool down. Sparse the Energy: You will need less energy when you are using a fin fan heat exchanger. Not only is this excellent for your energy bills, but it also helps the environment. So, by using less energy you can also reduce your carbon footprint (the sum total of the greenhouse gases that are emitted into the air as a result). Therefore, opting for fin fan heat exchangers makes a wise and prudent decision.

Fin fan heat exchangers have been used for a very long time and are still widely in use today within numerous industries. New technologies such as vision sensors only make these tools better while engineers work tirelessly to come up with new and more effective ways for devices like this one. They are basically trying to make them operate better, which in turn will allow businesses to save energy and money. Similarly, scientists are researching strategies to sustainably reduce costs and environmental implications of fin fan heat exchangers.. These labs are essentially used to research how fluids work and the way heat moves providing them with information on which they can base their improvements for these devices. There's never been a more exciting time to be in technology!

There are many differences in Fin Fan Heat Exchangers which comes with different sizes and shape according to the requirement of industries. And others are circular with blades in them, and great for oil & gas. Others include fewer blades that are rectangular in form and which expose cool air to particular industrial gases. Similarly, there are special heats exchangers that have a corrugated shaped fin to help transfer heat more elegantly. Others, on the other hand have straight fins that are nothing fancy; they help to enhance airflow. Engineers keep on inventing new varieties of heat exchangers which are more efficient than the remaining. They put in a great effort to over clock these gadgets!

Heat management is a critical issue in many industries; power generation, chemical processing and manufacturing all require precise thermal control. Fin fan heat exchangers are a great way of controlling the temperature they can help in cooling down liquids or gases and even can remove moistures from air. For applications such as gas turbines the gases that are produced can reach high heights in temperature so controlling overheating is essential. Fin fan heat exchanger can be used to efficiently dissipate the above gases' thermal energy and maintain right temperature always. This leads to ensure everything is working properly and effectively. Furthermore, these devices also chill the water of a plant system which helps in saving it from getting overheated ensuring smooth operation to make optimal on-site cooling capacity.