Heat Exchanger and Condenser? These are obviously very necessary machines, which is in charge of maintaining constant either cool or hot. They are like energy; they transfer heat from one place to another. Heat exchangers and condensers can be found almost everywhere from your home refrigerator all the way up to big industrial factories where they are used for several different things.

Similarly two liquids flow together in heat exchangers and condensers but they do not mix up. One of such liquid is known as hot that means it gets heat. The other liquid is the “cool” one which cools down. As the hot liquid flows by the cool one, it loses its heat to that cooler liquid. This process serves to moderate the overall temperature, allowing the hot liquid to cool off and enabling the cold liquid heat up. It is such a simple method but so crucial in temperature control of numerous systems.

The importance of heat exchangers and condensers are significant in various industries as well as applications. For example, they help turn crude oil into products such as gasoline and diesel fuel that you use every day at the gas station. They are the workhorses of power plants, performing mission-critical functions such as converting steam into electricity to light and heat our homes and businesses. Also, in the food and beverage industry heat exchangers are used to get milk or other foods heated enough for us that it does not cause severe illnesses. Which is called pasteurization, and make kills bad bacteria that can actually hurt us.

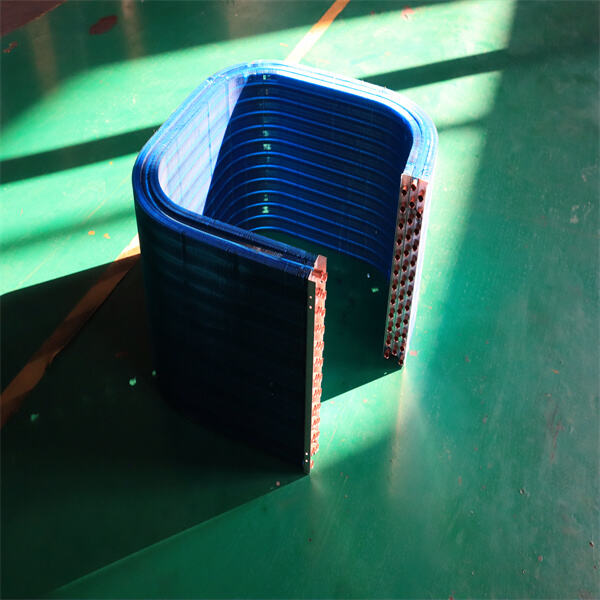

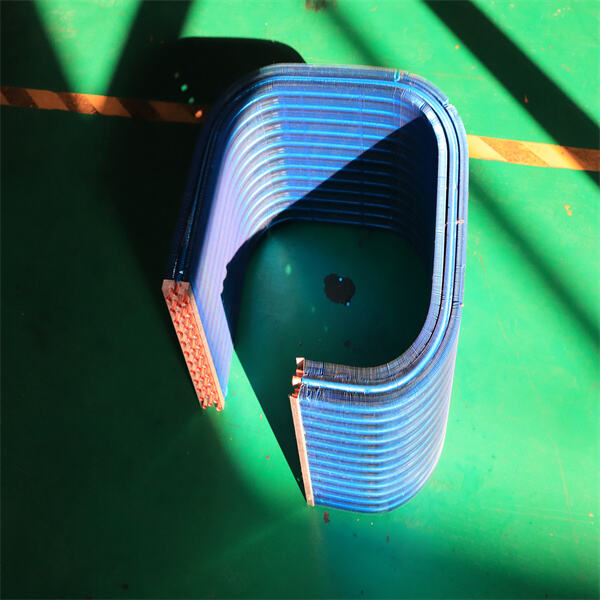

Designing heat exchangers and condensers is a daunting process. When they are building out these systems, engineers need to consider so many things. They need to think about the kind of fluids they are using, how much heat it is that needs to be transferred and what temperatures/pressures the system can handle. Additionally, they would like the system to be effective in terms of performance, negligible in terms of cost impact both for its manufacturing and operation. In order to improve these machines, and in many cases make them more efficient or effective, engineers may use a computer program to simulate how such systems will behave under different conditions. This helps them be able to predict performance and strengthen it.

Like all mechanicals, you will require skilled professionals to perform heating exchanger and condenser repairs over time. This can be from simply cleaning the machines, through to examining them for any wear and tear or needing parts replaced. Why… repairs such you ask!! Well, the leaks are fixed, broken parts replaced and maybe even new equipment being installed to improve performance. Having a good state of the heat exchanger and condenser would be crucial for their operation safety as well efficiency. Jamie Squire LLCGetty Images Maintenance is key to help prevent larger issues in the future.

For the record, heat exchangers and condensers are come a long way with technology advancement. A new fascinating concept is the utilization of nanofluids — special fluids with minute particles that can aid in enhancing heat transfer significantly. This could allow these machine to work still higher. A 3D printer is used in yet another concept to manufacture heat exchangers and condensers that are not only more efficient, but also cost less when produced. They are also investigating the preparation of materials and designs that can contribute to an even more reliable, safe, efficient operation for these systems.